YOUR BUSINESS AUTHORITY

Springfield, MO

YOUR BUSINESS AUTHORITY

Springfield, MO

In December, you purchased a Leica BLK360 laser-imaging scanner to make 3-D computer-aided designs. How has this impacted your firm?

A lot of what we’re doing is detailed work that’s best represented in a 2-D environment, but as time goes on, the 3-D environment is becoming more important. The tradesmen and laborers can see what they’re doing better, and it helps have a better product. That helps minimize field orders and change orders. You press a button and 360,000 data points are measured, and it takes a Google Street View and maps it in 3-D. We can go in and measure our clients’ facilities and give a visual representation of the place in hours – compared to days and weeks. And we have a lot more data that’s secure.

How much did you pay for the machine?

That’s a $17,000 item, which is not bad compared to a few years ago. It would have been $100,000, and it would do monochrome. You’d scan all the points and see a bunch of blue points. Now, it takes pictures. You can walk through the place and see it in color.

What has been the client response?

We’ve been using it for three or four projects. It’s helped them visualize what they want to do and then reduce our field time because our folks can press the button, gather data saved on an iPad, and then we can go back and do detailed drawings and measurements. We can do measurements on a plant that is three hours away from our office. That’s saving time and improving accuracy. We had an incident on one job where we got the model back and noticed a 2-foot difference on what we thought the ceiling was because there was a slope.

What are the downsides to the 3-D CAD process?

We have some [clients] who are still hesitant to having the pictures. Because of the sensitivity and confidentiality of our clients, they won’t always allow us to take that machine in there and capture all the data. That makes it a little tougher.

Is this 3-D laser-imaging equipment more common for engineering firms across the board?

It’s becoming a lot more common. We’ve done several jobs, though, where we’ve been hired just to document a facility. There are at least a couple of them measuring with laser tape and physical tapes. To measure a facility that’s hundreds of thousands of square feet can take weeks. We press a button, and we’re done. A big plant can be done in a day. Plus, we can ship that file to a remote headquarters and engineers who have never been in the plant can see inside the plant and see everything they need to see.

What do you charge for the service?

It would (be) a $17,000 bid on jobs that probably would have been in the $25,000 or $30,000 range – and they wouldn’t have gotten all the pictures and data points. We give them 2-D drawings, plus 3-D visualization of the plan. Everybody is going to have to have those pretty soon. Once clients see them, more and more expectation will be that you have to have that technology.

How is automation affecting your industry?

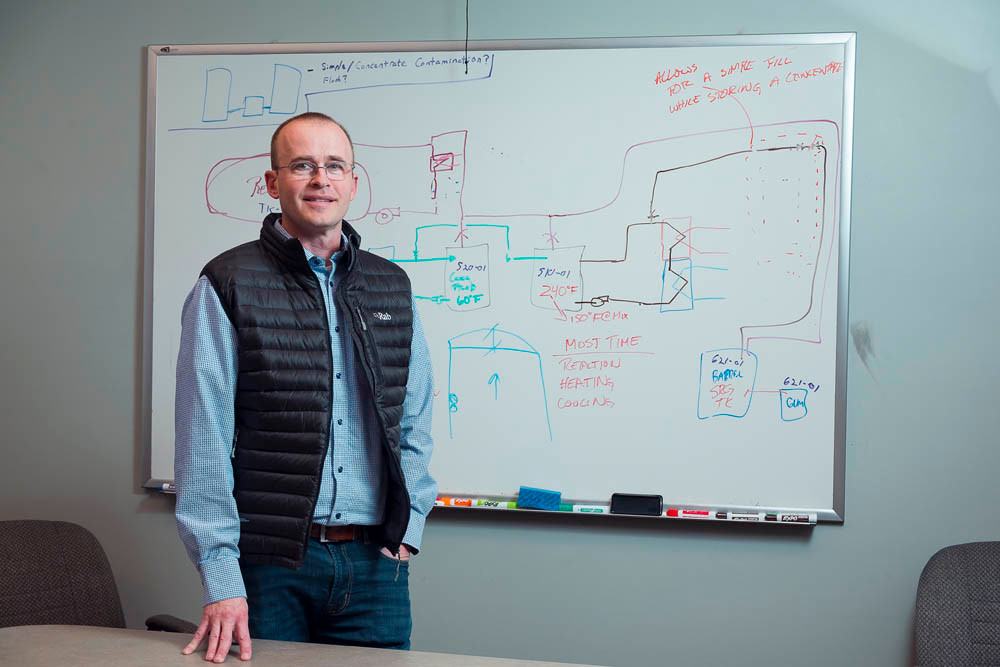

We have mechanical, process, civil, electrical and structural engineers, but we also have an automations control team. Our guys go in there and put in the industrial (programmable logic controllers) that make all the equipment work. We get to be involved with the design of the building to the design of the process, the machinery layout, utilities, and startup and automate the whole thing. Our engineers get to go out and bring it to life. Everyone is pushing for automation because it’s a more repeatable product, reduces cost and the safety issues.

So engineering firms aren’t worried about automation eliminating jobs?

It creates a lot of jobs, like the guys that we hire. They’re higher-paying jobs, and there are opportunities, especially in this environment. If people are willing to learn and have a little bit of a work ethic, they will be able to find jobs. Their jobs may change. There is constant change. Change is going to happen, so once you bite off that chunk in your mind and decide, “I’m going to have to learn something,” those arguments about losing jobs don’t hold as much water.

Scott Bybee can be reached at sbybee@escfirm.com.

Delta Roofing founder dies at 85

Cox College switching leaders ahead of Alliance for Healthcare Education transition

Curb Appeal: 23 high-end homes hit market

'Civil War' opens at No. 1 at domestic box office

Four arrested over theft of $300K in Lego kits